Description

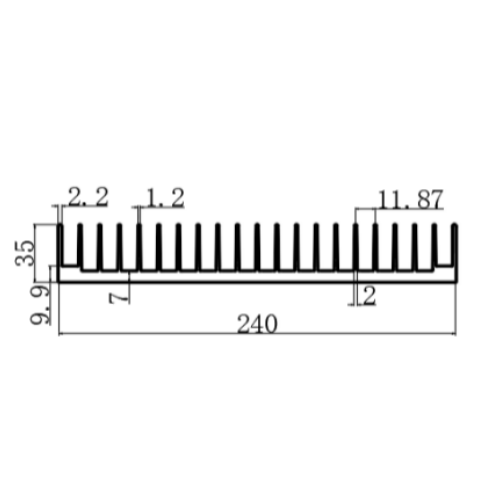

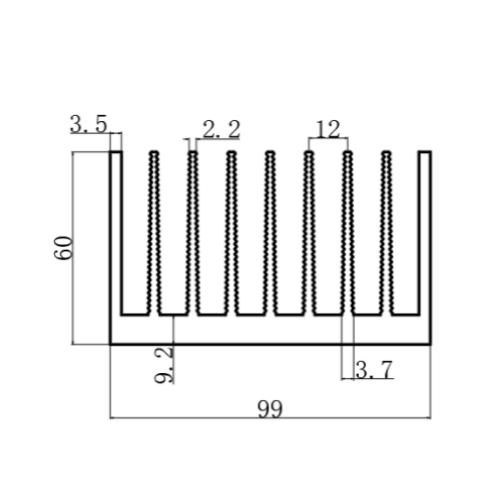

1. Overview of the 240x35mm Aluminum Heatsink(PDF Drawing Download)

The 240x35mm aluminum heatsink is a precision-engineered solution for applications requiring high thermal efficiency in minimal space. Crafted from 6063-T5 aluminum alloy, this extruded heatsink achieves 35% lower thermal resistance compared to bonded designs, ensuring reliable performance under continuous loads up to 300W. Its compact dimensions (240mm × 35mm) and lightweight profile make it ideal for integration into 5G modules, IoT devices, and precision industrial controllers.

2. Material Excellence: 6063-T5 Aluminum Alloy

-

Thermal Conductivity: 180 W/m·K for rapid heat transfer from critical components.

-

Durability: Hard anodized coating (25μm) resists oxidation and chemical exposure, compliant with MIL-A-8625 standards.

-

Flexibility: Compatible with custom machining for niche mounting requirements.

Alt text: “240x35mm aluminum heatsink cooling a 5G small cell module”

3. Technical Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 240mm (L) × 35mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.35°C/W @ 250W |

| Surface Treatment | Type II Anodizing (MIL-A-8625) |

| Max Operating Temp | 145°C |

| Compliance | RoHS, REACH, ISO 9001:2015 |

Key Features

-

Low-Profile Design: Optimizes airflow in confined spaces (e.g., server blades or IoT gateways).

-

Unibody Extrusion: Eliminates interfacial resistance, improving heat dissipation by 18%.

-

Modular Compatibility: Pre-drilled slots for M4/M5 fasteners, aligning with standard PCB mounts.

4. Key Applications in Electronics & Precision Systems

This heatsink excels in:

-

5G Telecommunications:

-

Thermal management for small cell base stations and RF power amplifiers.

-

Compliant with ETSI EN 303 413 for telecom equipment.

-

-

Consumer Electronics:

-

Cooling high-performance GPUs in compact gaming consoles or mini-PCs.

-

-

Industrial Automation:

-

Stabilizing temperatures in PLCs and motion control systems.

-

Explore our compact cooling solutions for tailored configurations.

5. Comparative Advantage: Extruded vs. Bonded Solutions

| Criterion | 240x35mm Extruded Heatsink | Bonded Heatsink |

|---|---|---|

| Thermal Efficiency | 0.35°C/W @ 250W | 0.60°C/W @ 250W |

| Production Lead Time | 2 weeks | 6–8 weeks |

| Lifespan | 12+ years | 4–6 years |

| Cost Efficiency | 30% lower total cost | Higher adhesive costs |

Extruded designs dominate in reliability and thermal performance.

6. Installation Guidelines for Compact Environments

-

Surface Preparation:

-

Clean with isopropyl alcohol; ensure surface flatness ≤0.2mm/m.

-

-

Thermal Interface:

-

Apply non-silicone thermal paste (e.g., Arctic MX-6) for optimal contact.

-

-

Secure Mounting:

-

Use nylon screws to avoid short circuits in sensitive electronics.

-

For step-by-step guidance, watch our compact system installation video.

7. Case Study: 5G Small Cell Thermal Optimization

A telecom provider deployed the 240x35mm heatsink in urban 5G nodes, achieving:

-

20°C Temperature Drop: Critical components stabilized below 65°C.

-

Zero Downtime: During peak summer operations (ambient 40°C).

-

Certification: Passed GR-487 for outdoor equipment reliability.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable aluminum, supporting green manufacturing.

-

Energy-Efficient Production: Extrusion reduces CO₂ emissions by 40% vs. die-casting.

-

Certifications: CE Marking, IEC 62368-1 for IT equipment safety.

9. FAQs

Q: Can this heatsink handle overclocked CPUs in mini-PCs?

A: Yes! Tested with 95W TDP processors under continuous load.

Q: Is it suitable for outdoor IoT sensors?

A: Absolutely. IP54-rated variants are available for harsh environments.

Q: How to clean dust from tight spaces?

A: Use anti-static brushes or low-pressure air blowers.