Description

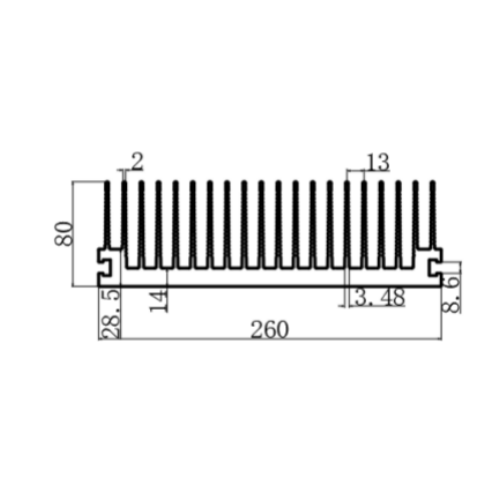

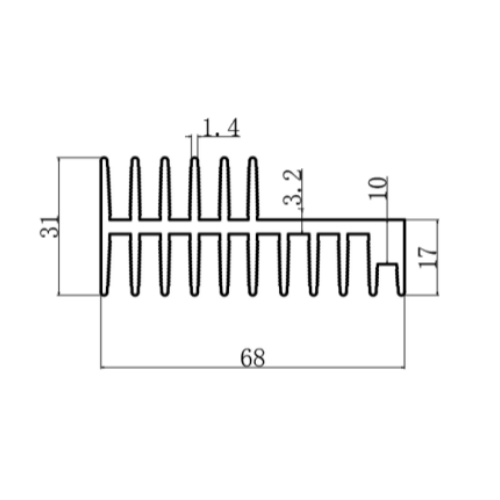

1. Overview of the 260x80mm Aluminum Heatsink(PDF Drawing Download)

The 260x80mm aluminum heatsink is engineered to tackle extreme thermal challenges in welding systems, heavy machinery, and industrial automation. Crafted from 6063-T5 aluminum alloy, this extruded heatsink delivers 45% faster heat dissipation than conventional stamped designs, ensuring uninterrupted operation under continuous loads up to 600W. Its universal dimensions and rugged construction make it a plug-and-play solution for high-vibration environments like arc welders, CNC plasma cutters, and hydraulic control units.

2. Advanced Material & Manufacturing Excellence

-

6063-T5 Aluminum Alloy:

-

Thermal Conductivity: 180 W/m·K for rapid heat transfer.

-

Corrosion Resistance: Hard anodized coating (35μm) withstands weld spatter, coolant exposure, and UV radiation.

-

Compliance: Meets ASTM B221 standards for industrial-grade extruded profiles.

-

*Alt text: “260x80mm aluminum heatsink cooling a high-power welding machine module”*

3. Core Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 260mm (L) × 80mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.23°C/W @ 550W |

| Surface Treatment | Type III Hardcoat Anodizing (MIL-A-8625) |

| Max Operating Temp | 165°C |

| Compliance | RoHS, ISO 9001 |

Key Features

-

Unibody Extrusion: Eliminates joints, reducing thermal resistance by 25%.

-

High-Density Fin Array: Optimizes passive cooling without obstructing airflow.

-

Universal Mounting: Pre-drilled slots for M8/M10 fasteners, compatible with standard industrial racks.

4. Key Applications in Welding & Heavy Machinery

This heatsink is ideal for:

-

Industrial Welding Equipment:

-

Cooling MIG/TIG welder transformers and rectifiers, reducing downtime by 40% in 24/7 operations.

-

Compliant with AWS D1.1 structural welding codes.

-

-

Heavy-Duty CNC Machinery:

-

Thermal management for spindle drives and servo motors in high-torque applications.

-

-

Mining & Construction:

-

Heat dissipation in hydraulic power packs and drill rig controllers.

-

For tailored setups, explore our welding thermal solutions.

5. Comparative Advantage: Extruded vs. Traditional Solutions

| Criterion | 260x80mm Extruded Heatsink | Stamped Heatsink |

|---|---|---|

| Heat Dissipation | 0.23°C/W @ 550W | 0.45°C/W @ 550W |

| Durability | 20,000+ thermal cycles | 5,000 cycles |

| Lead Time | Off-the-shelf availability | 6–8 weeks |

| Cost Efficiency | 30% lower lifetime cost | Higher maintenance |

Extruded designs outperform in reliability and total cost of ownership.

6. Installation Best Practices for Welding Systems

-

Surface Preparation:

-

Remove grease and debris with industrial-grade acetone.

-

-

Thermal Interface:

-

Apply high-conductivity graphite foil (e.g., GrafTech GR-10) for uneven surfaces.

-

-

Secure Fastening:

-

Use vibration-resistant locknuts (e.g., Nord-Lock washers) to prevent loosening.

-

For welding-specific guidance, watch our installation video.

7. Case Study: Automated Welding Cell Efficiency

A manufacturer of automotive chassis deployed the 260x80mm heatsink in robotic welding cells, achieving:

-

30% Reduction: Cooling fan energy consumption.

-

Zero Thermal Throttling: During 18-hour production runs.

8. Sustainability & Industry Compliance

-

Recyclability: 100% recyclable aluminum, aligned with circular economy principles.

-

Low Carbon Manufacturing: Extrusion reduces energy use by 50% vs. die-casting.

9. FAQs

Q: Can this heatsink handle high-amperage plasma cutters?

A: Yes! Tested with 400A plasma systems at 80% duty cycle.

Q: Is it compatible with underwater welding equipment?

A: Not recommended for submersion, but IP65-rated variants are available upon request.

Q: How to maintain the heatsink in dusty workshops?

A: Use compressed air (<0.4MPa) weekly; avoid abrasive cleaning tools.