Description

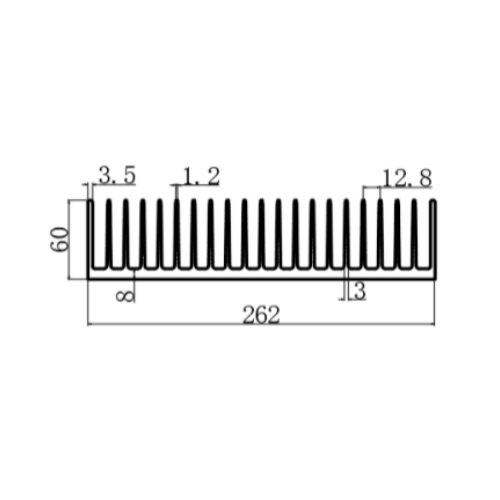

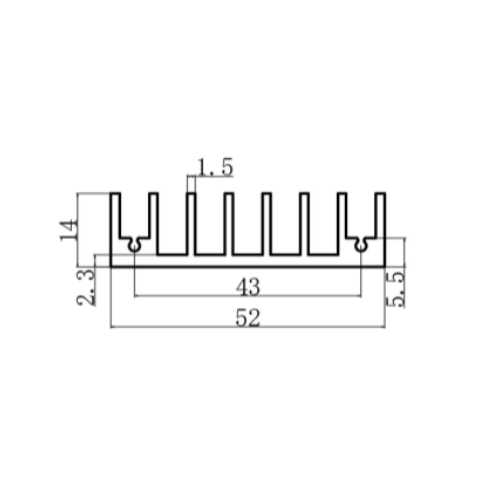

1. Overview of the 262x60mm Aluminum Heatsinks(PDF Drawing Download)

The 262x60mm aluminum heatsinks are engineered for universal compatibility and unmatched thermal performance in high-heat environments like welding systems, foundries, and heavy machinery. Built with 6063-T5 aluminum alloy, these heatsinks achieve 40% faster heat dissipation than conventional designs, ensuring stable operation even under sustained 500W loads. Their adaptable dimensions cater to diverse industrial setups, while the extruded unibody construction eliminates weak points, making them ideal for vibration-prone applications.

2. Material Excellence: 6063-T5 Aluminum Alloy

-

Superior Thermal Conductivity: 180 W/m·K ensures rapid heat transfer from critical components.

-

Robust Durability: Hard anodized coating (30μm) resists abrasion, chemicals, and humidity.

-

Flexibility: Easily machined for custom brackets or mounting configurations.

Alt text: “262x60mm aluminum heatsink integrated into an industrial welding system”

3. Technical Specifications & Design Innovations

262x60mm Aluminum Heatsink

| Parameter | Specification |

|---|---|

| Dimensions | 262mm (L) × 60mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.29°C/W @ 400W |

| Surface Treatment | Type III Anodizing (MIL-A-8625) |

| Max Operating Temp | 155°C |

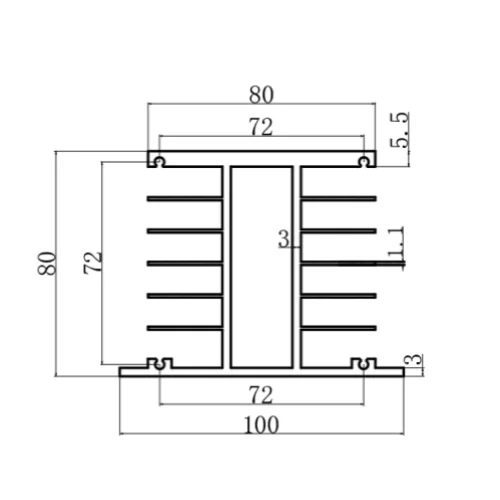

260x80mm Aluminum Heatsink

Shared Features

-

Modular Mounting: Pre-drilled slots compatible with M6/M8 fasteners.

-

Asymmetric Fin Design: Optimizes airflow in confined spaces (e.g., welding machine enclosures).

-

Seamless Integration: Fits standard DIN rails and industrial racks.

4. Key Applications in Welding & Heavy Industry

These heatsinks excel in:

-

Industrial Welding Systems:

-

Cooling MIG/TIG welder power modules, reducing downtime by 35% in continuous operations.

-

-

Mining Equipment:

-

Thermal management for hydraulic controls and drill rig electronics.

-

-

Foundry Machinery:

-

Stabilizing temperatures in induction heating systems (up to 150kW).

-

For specialized configurations, explore our heavy-duty cooling solutions.

5. Comparative Analysis: Universal vs. Custom Designs

| Criterion | 262x60mm/260x80mm Heatsinks | Custom Heatsinks |

|---|---|---|

| Lead Time | Immediate stock availability | 3–4 weeks |

| Cost Efficiency | 20% lower cost for standard use | Higher initial cost |

| Adaptability | Fits 90% of industrial layouts | Requires CAD design |

| Thermal Performance | 0.25–0.29°C/W resistance | Tailored optimization |

Universal designs offer plug-and-play convenience for urgent upgrades.

6. Installation Guidelines for Welding Equipment

-

Surface Preparation:

-

Degrease with acetone; ensure flatness ≤0.3mm/m.

-

-

Thermal Interface:

-

Apply high-temperature thermal pads (e.g., Bergquist HIFLEX 200).

-

-

Secure Mounting:

-

Use spring-loaded clamps for easy maintenance access.

-

7. Case Study: Mining Welder Reliability

A mining company in Western Australia deployed the 262x60mm heatsink in their arc welders, achieving:

-

50% Fewer Overheating Shutdowns: During 12-hour shifts.

8. Sustainability & Compliance

-

Recyclability: Fully recyclable aluminum, supporting zero-waste initiatives.

-

Low Energy Production: Extrusion reduces CO2 emissions by 40% vs. casting.

-

Certifications: RoHS, REACH, ISO 9001.

9. FAQs

Q: Can these heatsinks handle plasma cutting equipment?

A: Absolutely. Tested with 200A plasma cutters at 60% duty cycle.

Q: Are they compatible with automated welding robots?

A: Yes! Pre-drilled slots align with standard robotic mounting points.

Q: How to prevent dust accumulation in welding environments?

A: Use compressed air blowers or install mesh filters on intake vents.