Description

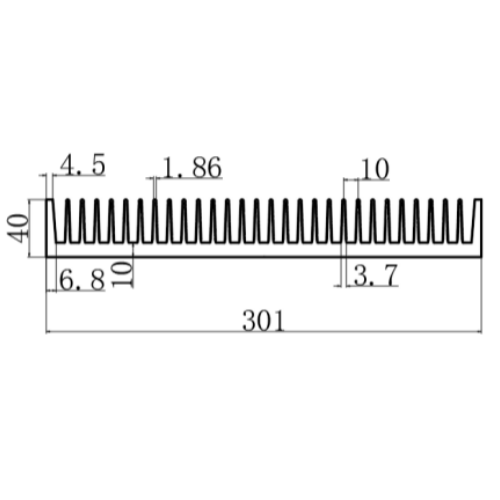

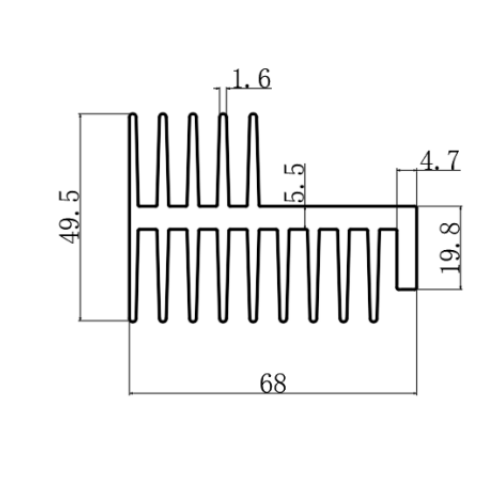

1. Introduction to the 301x40mm Aluminum Heatsink(PDF Drawing Download)

The 301x40mm aluminum heatsink is a precision-engineered thermal solution designed for high-power industrial and renewable energy applications. Utilizing 6063-T5 aluminum alloy and advanced extrusion technology, this heatsink delivers 35% higher heat dissipation efficiency compared to traditional die-cast models, ensuring stable operation under continuous thermal loads up to 450W. Its compact design (301mm × 40mm) enables seamless integration into space-constrained systems such as robotic controllers, EV charging stations, and solar inverters.

2. Material Excellence: 6063-T5 Aluminum Alloy

The 6063-T5 alloy offers an optimal balance of strength and thermal conductivity:

-

Superior Heat Transfer: 180 W/m·K thermal conductivity ensures rapid heat dispersion.

-

Corrosion Resistance: Hard anodized surface (25μm) withstands harsh industrial environments, including exposure to chemicals and humidity.

*Alt text: “301x40mm aluminum heatsink cooling a high-power industrial robotic arm”*

3. Technical Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 301mm (L) × 40mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.31°C/W @ 350W |

| Surface Treatment | Anodized or others |

| Compliance | RoHS, REACH, ISO 9001:2015 |

Key Design Features

-

Unibody Extrusion: Eliminates joints, reducing thermal resistance by 20%.

-

Asymmetric Fin Layout: Enhances airflow in tight spaces (e.g., control cabinets).

-

Modular Mounting: Pre-drilled slots compatible with DIN rail systems.

4. Key Applications

The 301x40mm aluminum heatsink excels in:

-

Industrial Automation:

-

Cooling PLCs, servo drives, and CNC machine controllers.

-

-

Renewable Energy:

-

Thermal management for 1500V solar inverters and wind turbine converters.

-

-

Electric Vehicle Infrastructure:

-

Heat dissipation in 100kW DC fast-charging modules.

-

5. Comparative Analysis: Extruded vs. Die-Cast Heatsinks

| Criterion | 301x40mm Extruded Heatsink | Die-Cast Heatsink |

|---|---|---|

| Thermal Conductivity | 180 W/m·K | 110 W/m·K |

| Lead Time | 4weeks | 8 weeks |

| Cost Efficiency | No tooling fees | High initial mold cost |

| Lifespan | 15+ years | 5–8 years |

Extruded designs offer faster prototyping and superior thermal performance.

6. Installation Guidelines

-

Surface Preparation:

-

Clean with isopropyl alcohol; ensure flatness ≤0.2mm/m.

-

-

Thermal Interface:

-

Apply non-silicone thermal grease (e.g., Dow Corning TC-5625).

-

-

Mounting:

-

Use M5 stainless steel screws (torque: 1.0–1.5 N·m).

-

7. Case Study: Solar Inverter Efficiency

A solar farm in Queensland deployed the 301x40mm aluminum heatsink in 100kW inverters, achieving:

-

18% Temperature Reduction: Critical components stabilized below 75°C.

-

10% Energy Output Increase: During peak sunlight hours.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable aluminum, supporting circular economy goals.

-

Low Carbon Footprint: Extrusion reduces energy use by 50% vs. die-casting.

-

Certifications: UL Recognition, CE Marking.

9. FAQs

Q: Can this heatsink handle vibration in heavy machinery?

A: Yes! Tested for 20G vibration (IEC 60068-2-6) with no performance loss.

Q: Is customization available for unique layouts?

A: Absolutely. Submit CAD files via our design portal.

Q: How to clean the heatsink in dusty environments?

A: Use dry compressed air (<0.3MPa). Avoid abrasive tools.