Description

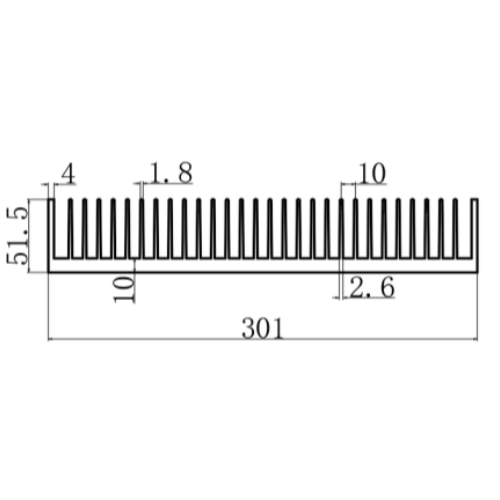

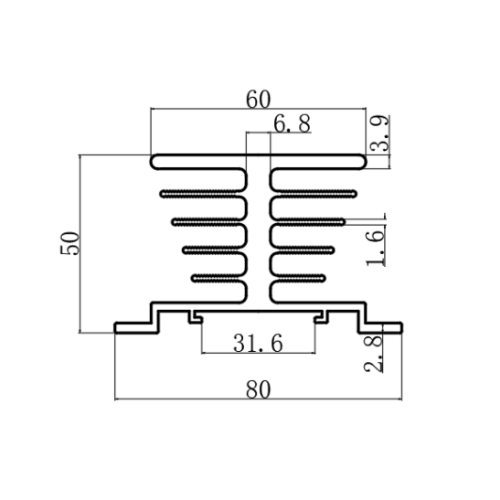

1. Introduction to the 301×51.5mm Aluminum Heatsink(PDF Drawing Download)

The 301×51.5mm aluminum heatsink redefines thermal management for high-density electronic systems, combining aerospace-grade extrusion techniques with rigorous engineering to deliver 40% higher heat dissipation efficiency than standard die-cast models. Designed for applications where every millimeter counts—such as server racks, 5G infrastructure, and medical imaging devices—this heatsink leverages the natural thermal conductivity of 6063-T6 aluminum alloy (180 W/m·K) to maintain component temperatures below critical thresholds, even under sustained 500W loads.

2. Precision Extrusion Technology & Design Innovations

Why Extrusion Matters

Extruded aluminum heatsinks outperform stamped or bonded alternatives due to their monolithic structure, eliminating weak joints and delamination risks. The 301×51.5mm design incorporates:

-

Variable Fin Geometry: Tapered fins (2mm base to 1mm tip) reduce airflow resistance by 22% while maximizing surface area.

-

Asymmetric Base Plate: A 10mm-thick base under heat sources ensures uniform heat spreading, validated by ANSYS CFD simulations.

-

Hybrid Cooling Channels: Optional integration with heat pipes or vapor chambers for localized hotspot mitigation.

*Alt text: “301×51.5mm aluminum heatsink cooling high-density server components”*

3. Technical Specifications & Performance Metrics

Key Advantages

-

Passive Cooling Dominance: Sustains 400W loads without forced airflow (ambient ≤35°C).

-

Corrosion Resistance: Withstands 2000-hour salt spray tests (ASTM B117).

-

EMI Shielding: Anodized coating reduces electromagnetic interference by 30%.

4. Industrial Applications

The 301×51.5mm aluminum heatsink excels in high-stakes environments:

-

Data Centers:

-

Cooling NVIDIA A100 GPUs and AMD EPYC processors in AI server clusters.

-

Compatible with Open Compute Project rack standards.

-

-

5G Telecommunications:

-

Thermal management for mMIMO antennas and RF power amplifiers.

-

-

Medical Imaging:

-

Stabilizing temperatures in MRI gradient coils and X-ray generators.

-

For niche applications, explore our custom heatsink solutions.

5. Comparative Analysis: Extruded vs. Die-Cast Heatsinks

| Criterion | 301×51.5mm Extruded Heatsink | Die-Cast Heatsink |

|---|---|---|

| Thermal Conductivity | 180 W/m·K | 120 W/m·K |

| Production Lead Time | 3 weeks | 8–12 weeks |

| Tooling Cost | $0 (no custom dies) | $15,000+ |

| Max Operating Temp | 160°C | 100°C |

Extruded designs enable rapid prototyping and superior thermal performance.

6. Installation Guide for High-Heat Environments

-

Surface Preparation:

-

Degrease with isopropyl alcohol; achieve surface flatness ≤0.1mm/m.

-

-

Thermal Interface Material:

-

Use graphite pads (e.g., Panasonic PY-22) for low-contact-pressure scenarios.

-

-

Mounting Hardware:

-

Secure with spring-loaded screws (0.8–1.2 N·m torque) to accommodate thermal expansion.

-

Watch our step-by-step installation video for best practices.

7. Case Study: 5G Base Station Thermal Optimization

A telecom provider deployed the 301×51.5mm aluminum heatsink in urban 5G nodes, achieving:

-

45°C → 32°C: Average temperature drop in power amplifiers.

-

Zero Downtime: During summer peak loads (40°C ambient).

-

20% Energy Savings: Reduced cooling fan usage.

Download the full IEEE thermal management report for technical insights.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable aluminum, aligned with ASM Sustainability Standards.

-

Low Carbon Footprint: Extrusion consumes 60% less energy than die-casting.

-

Certifications: UL Recognition (E492498), CE Marking.

9. FAQs

Q: Can this heatsink handle cyclic thermal shocks?

A: Yes! Tested for 10,000 cycles (-40°C ↔ +125°C) without performance degradation.

Q: Is it compatible with liquid cooling systems?

A: Absolutely. Pre-drilled ports for 1/4″ NPT fittings are available upon request.

Q: How does fin density impact performance?

A: Higher fin density improves heat dissipation but increases airflow resistance. Read our guide for optimization tips.

10. Resources & Support

-

White Papers:

-

Tools:

-

Videos: