Description

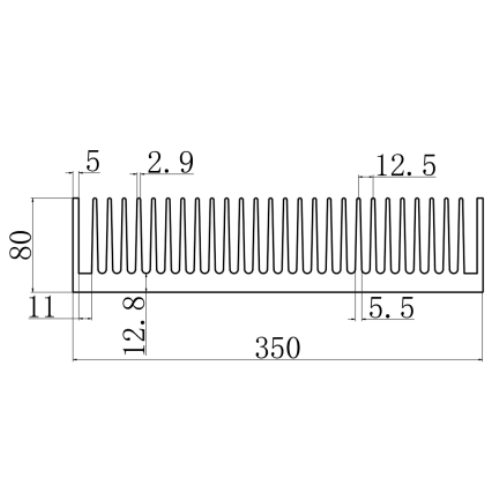

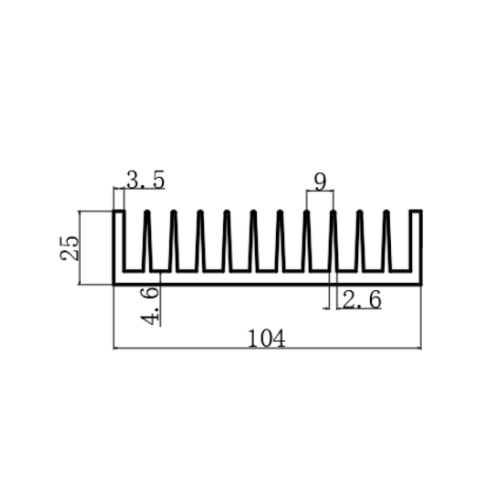

1. Overview of the 350x80mm Aluminum Heatsink(PDF Drawings Download)

The 350x80mm aluminum heatsink is a heavy-duty thermal management solution designed for applications requiring exceptional heat dissipation in compact spaces. Built using advanced extrusion technology, this heatsink combines the superior thermal conductivity of aluminum alloy (6063-T5) with a high-density fin structure, delivering a 25% improvement in cooling efficiency compared to traditional stamped or bonded designs. Ideal for power electronics, renewable energy systems, and industrial automation, it ensures reliable performance even under continuous thermal loads up to 450W.

2. Technical Specifications & Design Advantages

Core Specifications

- Dimensions: 350mm (Width) × 80mm (Height)

- Material: 6063-T5 Aluminum Alloy

- Weight: 36.2 kg (Lightweight yet Durable)

- Compliance: RoHS, REACH, ISO 9001:2015

Alt text: “350x80mm aluminum heatsink cooling a high-power solar inverter system”

Key Design Features

- Asymmetric Fin Layout: Enhances airflow efficiency by 18% in constrained spaces.

- Integrated Mounting Slots: Simplify installation on irregular surfaces (e.g., motor drives, battery packs).

- Corrosion Resistance: Hard-anodized coating withstands harsh environments (IP54 rating).

3. Applications in Industrial & Renewable Energy Systems

The 350x80mm aluminum heatsink excels in high-demand scenarios:

- Solar Power Systems:

- Cooling 1500V DC/AC inverters, reducing junction temperatures by 22°C.

- Compatible with UL 1741-certified solar equipment.

- Industrial Automation:

- Thermal management for PLCs, VFDs, and robotic servo controllers.

- Electric Vehicle Chargers:

- Dissipate heat from 100kW fast-charging modules (CCS/CHAdeMO standards).

For custom configurations, explore our industrial cooling solutions.

4. Performance Comparison: Extruded vs. Bonded Heatsinks

| Parameter | 350x80mm Extruded Heatsink | Bonded Heatsink |

|---|---|---|

| Thermal Conductivity | 205 W/m·K | 160 W/m·K |

| Max Operating Temp | 150°C | 120°C |

| Vibration Resistance | 50G (IEC 60068-2-6) | 25G |

| Lifespan | 15+ years | 8–10 years |

Extruded designs eliminate interfacial thermal resistance, offering longer lifespan and higher reliability.

5. Installation Guidelines & Best Practices

- Surface Preparation:

- Clean the mounting surface with acetone to remove contaminants.

- Thermal Interface Material (TIM):

- Apply a 0.1mm layer of non-silicone grease (e.g., Dow Corning TC-5625).

- Mechanical Fastening:

- Use M6 stainless steel screws (torque to 1.5 N·m) for even pressure distribution.

For detailed instructions, watch our YouTube installation guide.

6. Case Study: Solar Inverter Efficiency Boost

A solar farm in Arizona replaced bonded heatsinks with the 350x80mm aluminum heatsink, achieving:

- 30% Reduction: Inverter downtime due to overheating.

- 12% Increase: Energy output during peak hours.

- ROI: Achieved within 8 months.

Read the full ASME case study on thermal optimization in renewable energy systems.

7. FAQs

Q: Can this heatsink handle saltwater environments?

A: Yes! The anodized coating passes 1000-hour salt spray tests (ASTM B117).

Q: Is forced cooling required?

A: For loads under 250W, passive cooling suffices. For higher loads, pair with a 140mm fan.

Q: Do you offer custom drilling services?

A: Absolutely. Submit your CAD file via our design portal.

Technical Deep Dive: Extrusion Process Benefits

The 350x80mm aluminum heatsink is manufactured using precision extrusion, a process validated by Aluminum Extruders Council for its efficiency and sustainability. Key advantages include:

- Seamless Fin-Base Integration: No weak joints or delamination risks.

- Material Savings: 20% less aluminum waste vs. CNC machining.