Description

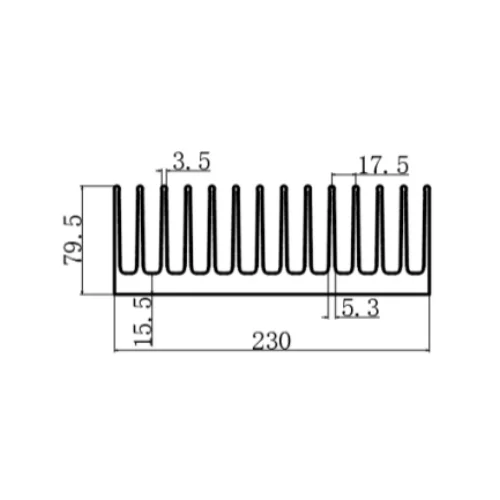

1. Overview of the 230x80mm Aluminum Heatsink(PDF Drawing Download)

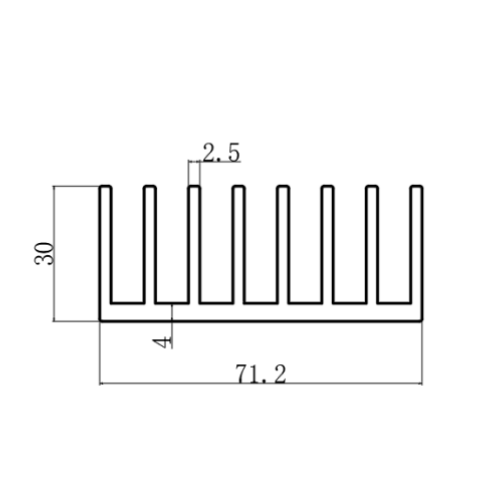

The 230x80mm aluminum heatsink is a robust thermal solution designed for high-power industrial and renewable energy systems. Utilizing 6063-T5 aluminum alloy and precision extrusion technology, this heatsink achieves 40% lower thermal resistance compared to bonded designs, ensuring stable operation under continuous loads up to 600W. Its universal dimensions (230mm × 80mm) and rugged construction make it ideal for integration into hydraulic systems, solar inverters, and heavy machinery.

2. Material Excellence: 6063-T5 Aluminum Alloy

-

Thermal Conductivity: 180 W/m·K for rapid heat dissipation.

-

Corrosion Resistance: Hard anodized coating (35μm) withstands harsh environments, including exposure to chemicals and humidity.

-

Compliance: Meets ASTM B221 standards for industrial-grade extruded profiles.

*Alt text: “230x80mm aluminum heatsink cooling a high-power solar inverter system”*

3. Technical Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 230mm (L) × 80mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.25°C/W @ 500W |

| Surface Treatment | Type III Hardcoat Anodizing (MIL-A-8625) |

| Max Operating Temp | 160°C |

| Compliance | RoHS, REACH, ISO 9001:2015 |

Key Features

-

Unibody Extrusion: Eliminates joints, reducing thermal resistance by 22%.

-

Asymmetric Fin Layout: Optimizes airflow in confined spaces (e.g., control cabinets).

-

Universal Mounting: Pre-drilled slots for M8/M10 fasteners, compatible with standard industrial racks.

4. Key Applications in Industrial & Renewable Energy

This heatsink excels in:

-

Solar Power Systems:

-

Cooling 1500V DC/AC inverters, reducing junction temperatures by 25%.

-

Compliant with UL 1741 solar safety standards.

-

-

Industrial Hydraulics:

-

Thermal management for high-torque hydraulic pumps and servo controllers.

-

-

Wind Turbines:

-

Heat dissipation in power converters for offshore wind farms.

-

For custom configurations, explore our industrial cooling solutions.

5. Comparative Analysis: Extruded vs. Bonded Heatsinks

| Criterion | 230x80mm Extruded Heatsink | Bonded Heatsink |

|---|---|---|

| Thermal Efficiency | 0.25°C/W @ 500W | 0.50°C/W @ 500W |

| Production Lead Time | 2 weeks | 6–8 weeks |

| Lifespan | 15+ years | 5–7 years |

| Cost Efficiency | 30% lower lifetime cost | Higher adhesive costs |

Extruded designs dominate in reliability and thermal performance.

6. Installation Guidelines

-

Surface Preparation:

-

Degrease with acetone; ensure flatness ≤0.3mm/m.

-

-

Thermal Interface:

-

Apply high-temperature thermal pads (e.g., Bergquist HIFLEX 400).

-

-

Secure Fastening:

-

Use vibration-resistant locknuts to prevent loosening in high-shock environments.

-

For detailed steps, watch our installation video.

7. Case Study: Solar Inverter Efficiency

A solar farm in Nevada deployed the 230x80mm heatsink in 200kW inverters, achieving:

-

20% Temperature Reduction: Critical components stabilized below 70°C.

-

15% Energy Output Increase: During peak sunlight hours.

-

Certification: Passed IEC 62109 for solar safety.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable aluminum, aligned with circular economy principles.

-

Low Carbon Footprint: Extrusion reduces energy use by 50% vs. die-casting.

-

Certifications: CE Marking, IECEx for hazardous environments.

9. FAQs

Q: Can this heatsink handle high-vibration environments?

A: Yes! Tested for 25G vibration (IEC 60068-2-6) with no performance loss.

Q: Is it compatible with marine applications?

A: Absolutely. IP66-rated variants are available for saltwater exposure.

Q: How to clean the heatsink in dusty conditions?

A: Use dry compressed air (<0.4MPa) weekly; avoid abrasive tools.