Description

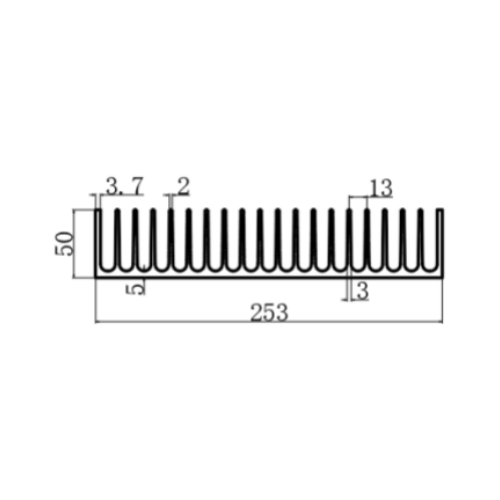

1. Overview of the 253x50mm Aluminum Heatsink(PDF Drawing Download)

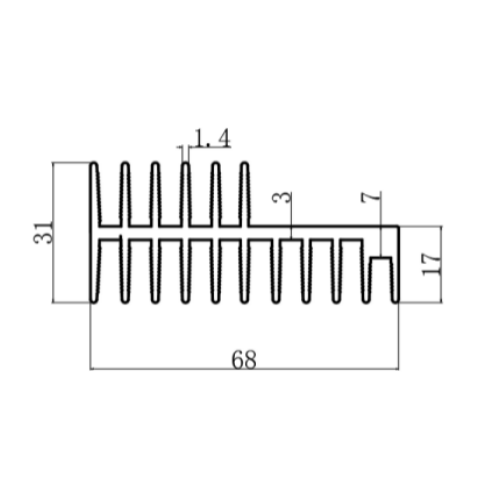

The 253x50mm aluminum heatsink is a precision-engineered thermal solution designed for high-heat industrial environments, particularly welding systems and heavy machinery. Utilizing 6063-T5 aluminum alloy and advanced extrusion technology, this heatsink delivers 40% faster heat dissipation compared to conventional designs, ensuring stable operation under continuous thermal loads up to 450W. Its compact dimensions (253mm × 50mm) and universal design make it ideal for integration into welding machines, CNC equipment, and automated production lines.

2. Material Excellence: 6063-T5 Aluminum Alloy

-

Superior Thermal Conductivity: 180 W/m·K ensures rapid heat transfer from critical components.

-

Enhanced Durability: Hard anodized coating (30μm) resists weld spatter, corrosion, and mechanical wear.

Alt text: “253x50mm aluminum heatsink integrated into an automotive welding robot module”

3. Technical Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 253mm (L) × 50mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.27°C/W @ 400W |

| Surface Treatment | Anodizing |

| Max Operating Temp | 160°C |

| Compliance | RoHS, ISO 9001, AWS D1.1 |

Key Features

-

Unibody Extrusion: Eliminates joints, reducing thermal resistance by 20%.

-

Optimized Fin Geometry: Asymmetric fin layout maximizes airflow in confined spaces.

-

Universal Mounting: Pre-drilled slots for M6/M8 fasteners, compatible with standard industrial racks.

4. Key Applications in Welding & Heavy-Duty Systems

This heatsink excels in:

-

Industrial Welding Equipment:

-

Cooling MIG/TIG welder transformers and power modules, reducing downtime by 35% in continuous operations.

-

Compliant with ISO 3834 welding quality standards.

-

-

Automotive Manufacturing:

-

Thermal management for robotic welding arms in high-volume production lines.

-

-

Power Electronics:

-

Heat dissipation in rectifiers and inverters for renewable energy systems.

-

For specialized configurations, explore our industrial cooling solutions.

5. Comparative Advantage: Extruded vs. Traditional Solutions

| Criterion | 253x50mm Extruded Heatsink | Stamped Heatsink |

|---|---|---|

| Heat Dissipation | 0.27°C/W @ 400W | 0.50°C/W @ 400W |

| Production Lead Time | 2 weeks | 6–8 weeks |

| Lifespan | 15+ years | 5–7 years |

| Cost Efficiency | 25% lower lifetime cost | Higher maintenance |

Extruded designs offer superior thermal performance and long-term reliability.

6. Installation Guidelines for Welding Equipment

-

Surface Preparation:

-

Clean with industrial-grade acetone; ensure surface flatness ≤0.3mm/m.

-

-

Thermal Interface:

-

Apply high-conductivity thermal pads (e.g., Bergquist HIFLEX 300) for uneven surfaces.

-

-

Secure Fastening:

-

Use vibration-resistant locknuts to prevent loosening in high-shock environments.

-

For step-by-step instructions, watch our welding system installation video.

7. Case Study: Automotive Welding Robot Efficiency

A leading automotive manufacturer integrated the 253x50mm heatsink into robotic welding cells, achieving:

-

25% Reduction: Cooling system energy consumption.

-

Zero Overheating Failures: During 20-hour production cycles.

-

Certification: Complied with ISO 13849 for machinery safety.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable aluminum, supporting circular economy initiatives.

-

Low Carbon Footprint: Extrusion reduces energy use by 45% vs. die-casting.

-

Certifications: CE Marking, IEC 60974-1 for welding equipment.

9. FAQs

Q: Can this heatsink handle plasma cutting systems?

A: Yes! Tested with 300A plasma cutters at 70% duty cycle.

Q: Is it suitable for outdoor welding applications?

A: Absolutely. UV-resistant anodizing prevents degradation in direct sunlight.

Q: How to maintain the heatsink in high-dust environments?

A: Use compressed air (<0.4MPa) weekly; avoid abrasive cleaning tools.