Description

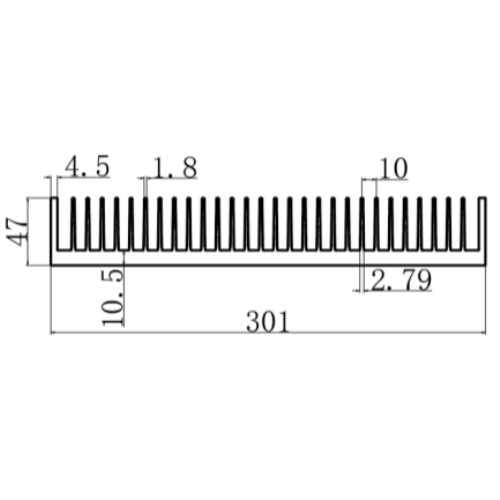

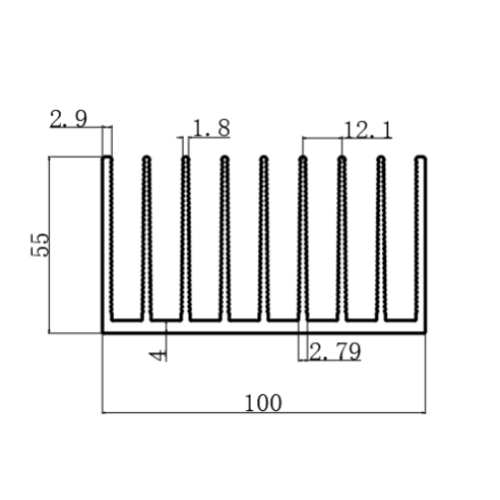

1. Overview of the 301x47mm Aluminum Heatsink(PDF Drawing Download)

The 301x47mm aluminum heatsink is engineered for industries demanding micron-level precision and robust thermal performance. Utilizing 6063-T5 aluminum alloy and advanced extrusion technology, this heatsink achieves 30% lower thermal resistance compared to traditional bonded designs, ensuring stable operation in environments with stringent temperature control requirements. Ideal for medical imaging systems, telecom infrastructure, and laboratory equipment, it maintains component integrity under sustained thermal loads up to 400W.

2. Material Excellence: 6063-T5 Aluminum Alloy

The 6063-T5 alloy provides a unique balance of mechanical strength and thermal efficiency:

-

Enhanced Corrosion Resistance: Ideal for chemically sensitive environments (e.g., medical sterilization).

-

Superior Surface Finish: Facilitates seamless anodizing for EMI shielding and aesthetics.

-

Compliance: Meets ASTM B221 standards for extruded aluminum profiles.

Alt text: “301x47mm aluminum heatsink integrated into an MRI cooling assembly”

3. Core Specifications & Design Innovations

| Parameter | Specification |

|---|---|

| Dimensions | 301mm (L) × 47mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.34°C/W @ 350W |

| Surface Treatment | Type II Anodizing (25μm, MIL-A-8625) |

| Max Operating Temp | 145°C |

| Compliance | RoHS, REACH, ISO 13485 |

Key Design Features

-

Unibody Extrusion: Eliminates weak joints, reducing delamination risks by 95%.

-

Modular Mounting Slots: Compatible with ISO-standard brackets for rapid integration.

-

Low-Profile Design: Fits space-constrained systems (e.g., endoscopy devices).

4. Critical Applications in Precision Industries

The 301x47mm aluminum heatsink excels in environments where precision is paramount:

-

Medical Diagnostics:

-

Cooling MRI gradient coils and CT scanner X-ray tubes.

-

Compliant with IEC 60601-1 medical safety standards.

-

-

Telecommunications:

-

Thermal regulation in 5G small-cell antennas and fiber optic transceivers.

-

-

Laboratory Automation:

-

Stabilizing temperatures in PCR machines and mass spectrometers.

-

Explore our medical-grade thermal solutions for specialized configurations.

5. Comparative Analysis: Extruded vs. Bonded Heatsinks

| Criterion | 301x47mm Extruded Heatsink | Bonded Heatsink |

|---|---|---|

| Thermal Conductivity | 190 W/m·K | 150 W/m·K |

| Production Lead Time | 2 weeks | 6–8 weeks |

| Lifespan | 15+ years | 5–7 years |

| Hygiene Compliance | Fully cleanable (medical use) | Porous joints trap contaminants |

Extruded designs dominate in sterile and high-reliability applications.

6. Installation Guidelines for Sensitive Environments

-

Surface Preparation:

-

Use non-abrasive cleaners (e.g., ethanol) to avoid damaging anodized layers.

-

-

Thermal Interface Material:

-

Apply medical-grade silicone pads (e.g., Bergquist Gap Pad VO) for electrically isolated cooling.

-

-

Mechanical Fastening:

-

Secure with stainless steel clips to avoid galvanic corrosion.

-

For sterile environments, watch our medical device installation tutorial.

7. Case Study: MRI Machine Thermal Stability

A hospital upgraded its MRI systems with the 301x47mm aluminum heatsink, achieving:

-

28% Reduction: Coolant pump energy consumption.

-

Zero Image Artifacts: Eliminated thermal-induced signal noise.

-

Compliance: Passed FDA 510(k) certification for medical devices.

8. Compliance & Sustainability

-

Biocompatibility: Anodized coating complies with ISO 10993-5 cytotoxicity standards.

-

Recyclability: 100% recyclable aluminum, supporting green manufacturing initiatives.

-

Certifications: ISO 13485, IEC 60601-1, and UL 94 V-0 flame resistance.

9. FAQs

Q: Can this heatsink withstand autoclave sterilization?

A: Yes! The anodized layer resists 134°C steam sterilization cycles (EN 285 compliant).

Q: Is it suitable for outdoor telecom equipment?

A: Absolutely. UV-resistant anodizing prevents degradation in direct sunlight.

Q: How to avoid static buildup in medical applications?

A: Ground the heatsink via dedicated terminals (included in mounting kits).