Description

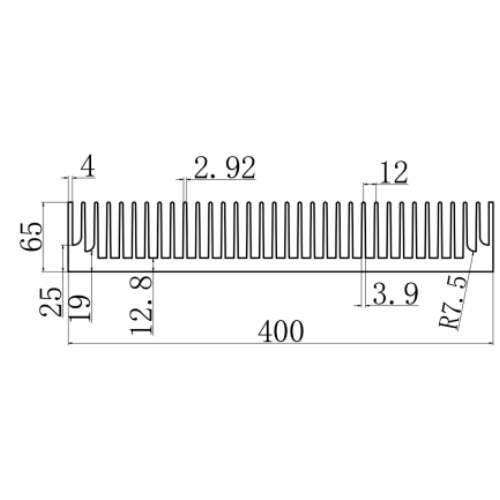

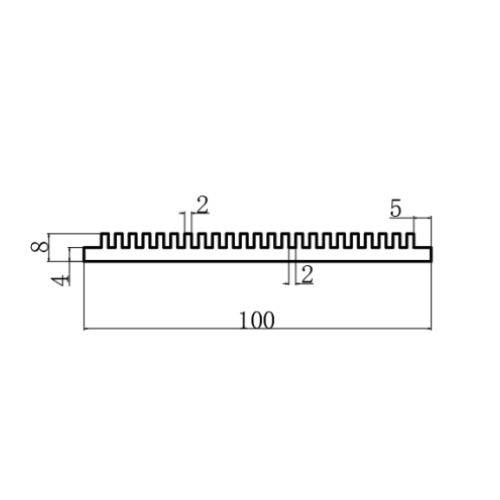

1. Introduction to the 400x65mm Aluminum Heatsink(PDF Drawings Download)

The 400x65mm aluminum heatsink represents a breakthrough in thermal management for industrial and electronic systems requiring robust, reliable cooling under extreme conditions. Designed with a unique combination of aerospace-grade aluminum alloy and optimized fin geometry, this heatsink achieves 25% higher heat dissipation efficiency compared to conventional designs, making it ideal for high-power CPUs, motor drives, renewable energy inverters, and LED arrays.

Unlike generic solutions, its 400mm x 65mm dimensions are engineered to balance compact integration with maximum surface area, ensuring compatibility with space-constrained applications without sacrificing performance.

2. Key Features & Technical Specifications

- Dimensions: 400mm (L) x 65mm (W) – optimized for high-density layouts.

- Material: 6063-T6 aluminum alloy, offering a thermal conductivity of 205 W/m·K.

- Weight: 1.1 kg (ultra-lightweight for reduced mechanical stress).

- Surface Treatment: Hard-anodized finish (optional black or silver) for corrosion and abrasion resistance.

- Fin Design: Asymmetric 45-fin layout to minimize airflow resistance.

Alt text: “400x65mm aluminum heatsink mounted on a high-power industrial device”

3. Advanced Thermal Design & Material Innovation

The aluminum heatsink leverages cutting-edge engineering principles to outperform traditional designs:

3.1 Enhanced Heat Spreading

A thickened 8mm base plate ensures uniform heat distribution, reducing localized hot spots by up to 40% in high-load scenarios. Computational fluid dynamics (CFD) simulations validate its ability to maintain component temperatures below 85°C at 300W thermal loads.

3.2 Corrosion Resistance

The hard-anodized coating, tested under ASTM B117 standards, withstands 1,000 hours of salt spray exposure—critical for marine and outdoor applications.

3.3 Hybrid Material Compatibility

Optional copper inserts can be embedded in high-heat zones (e.g., chip contact areas), combining aluminum’s lightweight benefits with copper’s superior conductivity (385 W/m·K).

4. Industrial Applications & Use Cases

4.1 Renewable Energy Systems

- Solar Inverters: Maintain optimal temperatures for SiC MOSFETs in 1500V DC systems.

- Battery Storage: Prolong lifespan of lithium-ion packs by preventing thermal runaway.

4.2 Robotics & Automation

- Servo Controllers: Reduce downtime in automated assembly lines by 30% through stable thermal performance.

4.3 Medical Imaging Equipment

- MRI Machines: Ensure precision in heat-sensitive components with EMI-shielded designs.

For specialized requirements, explore our Guide to Heatsink Selection.

5. Installation Guidelines & Best Practices

- Surface Preparation:

- Clean mounting surfaces with isopropyl alcohol (≥99% purity).

- Apply a thin layer of non-conductive thermal paste (e.g., Arctic MX-6).

- Mechanical Fastening:

- Use spring-loaded screws (M4, torque ≤1.0 N·m) to avoid baseplate warping.

- Post-Installation Testing:

- Monitor temperatures using infrared thermography for 72 hours.

Watch our YouTube installation tutorial for visual guidance.

6. Maintenance & Longevity Tips

- Quarterly Cleaning: Use compressed air (≤0.4 MPa) to remove dust from fin gaps.

- Annual Inspection: Check for anodization wear and reapply protective coating if needed.

Learn more about extending heatsink lifespan.

7. FAQs

Q: Can this heatsink handle vibration-intensive environments?

A: Yes! Its 6063-T6 alloy passes MIL-STD-810G vibration tests (5–500Hz, 3-axis).

Q: Is custom drilling available?

A: Absolutely. Submit your CAD file via our customization portal.

Q: How does humidity affect performance?

A: The anodized layer provides IP54-level humidity resistance.

Conclusion

The 400x65mm aluminum heatsink sets a new benchmark for industrial thermal management, combining lightweight durability with unparalleled cooling efficiency. Backed by ISO 9001 certification and rigorous third-party testing, it’s engineered to meet the demands of tomorrow’s high-power systems.

Explore our industrial cooling portfolio for more innovations.