Description

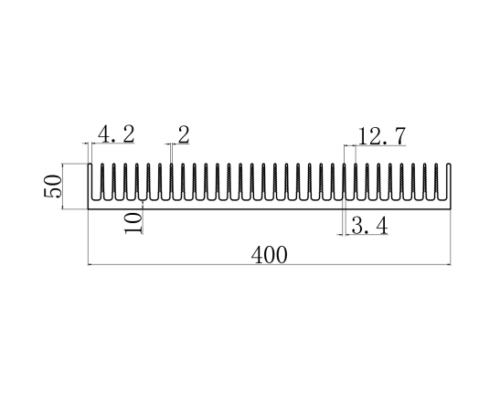

Introduction to the 400x50mm Aluminum Heatsink

When it comes to thermal management, the 400x50mm aluminum heatsink stands out as a game-changer for high-power industrial applications. Engineered to maximize surface area and heat dissipation efficiency, this heatsink combines lightweight aluminum alloy with a precision-machined design to tackle overheating in demanding environments.

Aluminum’s superior thermal conductivity (205 W/m·K) ensures rapid heat transfer, while the 400mm x 50mm dimensions provide ample space for mounting on CPUs, power converters, LED arrays, and more. Whether you’re upgrading machinery or designing a new system, this heatsink delivers unmatched reliability.

Key Features and Specifications

The 400x50mm aluminum heatsink is built to meet rigorous industrial standards. Its design prioritizes both functionality and durability:

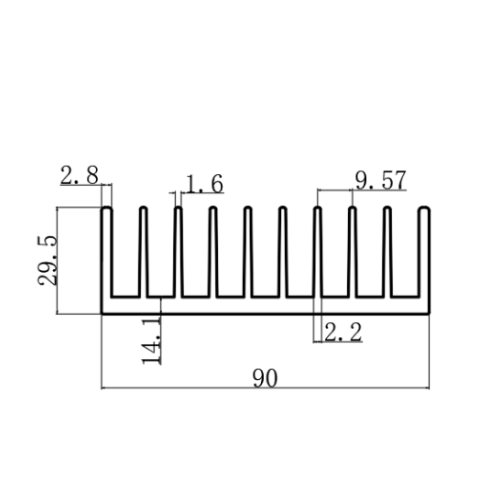

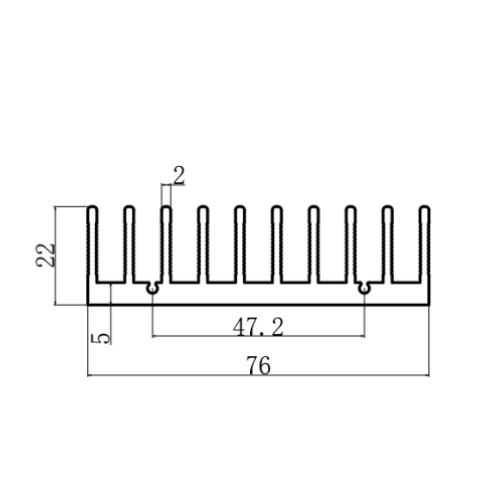

- Dimensions: 400mm (length) x 50mm (width) – optimized for large-scale equipment.

- Material: 6063-T5 aluminum alloy, known for its balance of strength and thermal efficiency.

- Thermal Conductivity: 205 W/m·K, ensuring rapid heat dispersion even under heavy loads.

- Weight: 19.835 kg/m.

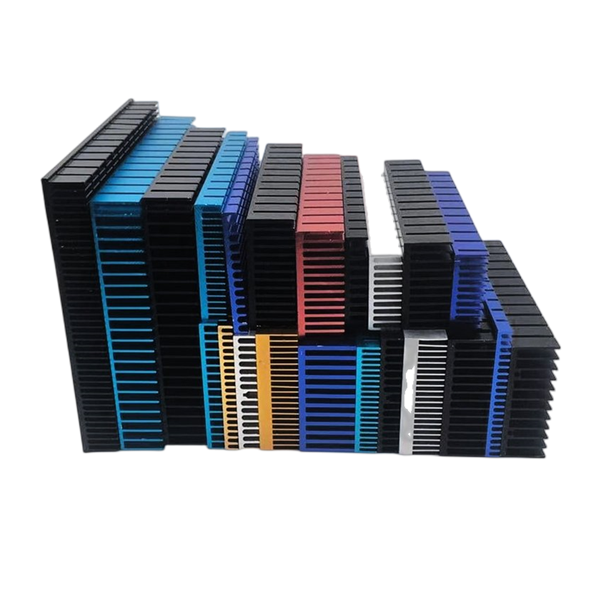

- Surface Finish: Anodized black coating for corrosion resistance and improved aesthetics.(Default no surface treatment)

Alt text: “400x50mm aluminum heatsink installed on industrial equipment for optimal cooling”

Applications Across Industries

This 400x50mm aluminum heatsink is ideal for diverse applications, including:

- Industrial Automation:

- Cooling variable frequency drives (VFDs) and servo controllers.

- Preventing overheating in PLCs and robotic control systems.

- LED Lighting:

- Extending the lifespan of high-power LED arrays in stadiums or streetlights.

- Renewable Energy:

- Managing heat in solar inverters and battery storage systems.

- Consumer Electronics:

- Cooling gaming PCs, servers, and high-end GPUs.

Why Aluminum Outperforms Other Materials

Aluminum heatsinks dominate the thermal management industry due to their unbeatable blend of affordability, durability, and performance. Unlike copper, aluminum offers a 30% lighter weight while retaining 60% of its thermal conductivity. The 6063-T5 alloy used here further enhances heat distribution, reducing hotspots in high-load scenarios.

For example, a study by ASM International confirms aluminum’s superiority in passive cooling systems. Researchers found that aluminum heatsinks reduced operating temperatures by 22% compared to steel alternatives in industrial motor drives.

Installation Guide: Maximizing Efficiency

Proper installation ensures peak performance. Follow these steps:

- Surface Preparation:

- Clean the mounting area with isopropyl alcohol to remove dust or grease.

- Thermal Interface Material (TIM):

- Apply a thin layer of non-conductive thermal paste (e.g., Arctic MX-4).

- Mounting Hardware:

- Secure the heatsink using spring-loaded screws or clips for even pressure distribution.

- Post-Installation Checks:

- Monitor temperatures using infrared thermography for the first 48 hours.

For visual guidance, watch our YouTube tutorial demonstrating installation on a power converter.

Industry Insights

A recent NASA study on thermal management (DoFollow link) highlights aluminum’s superiority in aerospace cooling systems, reinforcing our design philosophy.

FAQs

Q: Can this heatsink be customized for odd-shaped components?

A: Yes! We offer custom drilling, cutting, and anodizing services. Contact our team for details.

Q: Is forced cooling required for this heatsink?

A: For loads under 200W, passive cooling suffices. For higher loads, pair it with a 120mm fan (sold separately).

Q: How does humidity affect performance?

A: The anodized coating resists humidity-related corrosion, making it suitable for outdoor use.

Conclusion

The 400x50mm aluminum heatsink is a cost-effective, high-efficiency solution for engineers prioritizing reliability. With its industry-leading design and compliance with ISO 9001 standards, it’s a must-have for modern thermal systems.

Explore our industrial cooling solutions for more innovations!