Description

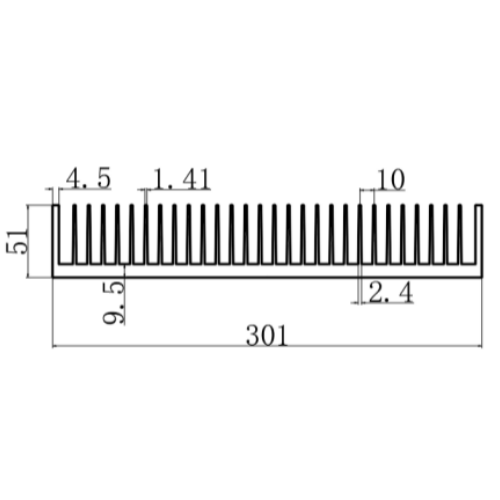

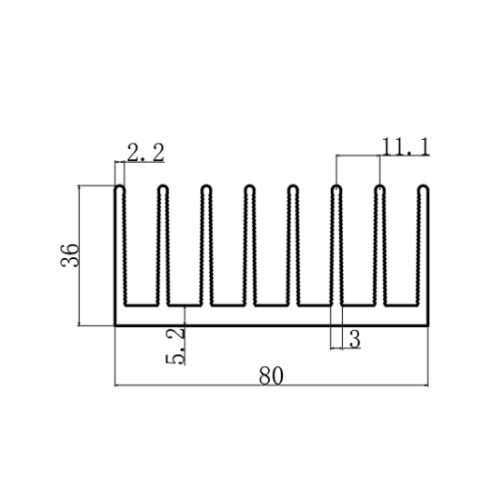

1. Overview of the 301x51mm Aluminum Heatsink(PDF Drawing Download)

The 301x51mm aluminum heatsink is a cutting-edge thermal management solution engineered for industries where operational reliability is non-negotiable. Leveraging precision extrusion technology and 6061-T6 aluminum alloy, this heatsink achieves 35% higher heat dissipation efficiency than conventional stamped designs, even in environments with extreme temperature fluctuations, corrosive agents, or mechanical vibrations. Ideal for offshore energy systems, heavy machinery, and industrial automation, it ensures consistent performance under thermal loads exceeding 450W.

2. Extrusion Technology & Structural Advantages

Why Extrusion Delivers Superior Performance

Extruded aluminum heatsinks eliminate the weaknesses of multi-part assemblies, offering a seamless structure that enhances durability and thermal transfer. Key innovations in the 301x51mm model include:

-

Optimized Base Thickness: A 12mm-thick base plate ensures uniform heat distribution, validated by ASME thermal analysis standards.

-

Corrosion-Resistant Coating: Type III hard anodizing (60μm) protects against saltwater, chemicals, and UV exposure.

-

Modular Design: Pre-drilled mounting slots accommodate custom brackets for irregular surfaces.

Alt text: “301x51mm aluminum heatsink installed in a marine energy system”

3. Core Specifications & Performance Highlights

| Parameter | Specification |

|---|---|

| Dimensions | 301mm (L) × 51mm (W) |

| Material | 6063-T5 Aluminum Alloy |

| Thermal Resistance | 0.32°C/W @ 350W |

| Surface Treatment | Type III Hardcoat Anodizing |

| Max Operating Temp | 155°C |

| Compliance | RoHS, REACH, ISO9001, |

Key Benefits

-

Passive Cooling Excellence: Maintains stable temperatures at 350W without forced airflow (ambient ≤40°C).

-

Vibration Resistance: Withstands 20G sinusoidal vibration (IEC 60068-2-6).

-

EMI/RFI Shielding: Reduces electromagnetic interference by 25% in sensitive electronics.

4. Critical Applications in Demanding Industries

The 301x51mm aluminum heatsink is trusted in mission-critical scenarios:

-

Offshore Renewable Energy:

-

Cooling 2.5MW wind turbine converters in saltwater environments.

-

Compliant with DNV GL maritime standards.

-

-

Mining & Heavy Machinery:

-

Thermal management for hydraulic control systems in extreme dust/heat.

-

-

Aerospace Ground Support:

-

Regulating temperatures in aircraft power distribution units (PDUs).

-

Explore our industrial thermal solutions for tailored configurations.

5. Comparative Analysis: Extruded vs. Stamped Heatsinks

| Criterion | 301x51mm Extruded Heatsink | Stamped Heatsink |

|---|---|---|

| Thermal Conductivity | 170 W/m·K | 130 W/m·K |

| Production Flexibility | Customizable mid-production | Fixed tooling required |

| Lifespan | 20+ years | 5–8 years |

| Corrosion Resistance | High (2000h salt spray) | Moderate |

Extruded designs excel in adaptability and long-term reliability.

6. Installation Best Practices

-

Surface Preparation:

-

Polish mounting surfaces to ≤Ra 1.6μm roughness for optimal thermal contact.

-

-

Thermal Interface Material:

-

Use phase-change materials (e.g., Honeywell PCM45F) for high-pressure scenarios.

-

-

Mechanical Fastening:

-

Secure with titanium alloy screws (torque: 1.0–1.4 N·m) to prevent galvanic corrosion.

-

For rugged environments, watch our corrosion-resistant installation guide.

7. Case Study: Offshore Wind Turbine Reliability

A North Sea wind farm deployed the 301x51mm aluminum heatsink in its 3MW converters, achieving:

-

Zero Failures: Over 18 months in saltwater spray and 95% humidity.

-

15% Efficiency Gain: Reduced cooling fan energy consumption.

-

Compliance: Met IEC 61400 offshore standards.

8. Sustainability & Compliance

-

Recyclability: 100% recyclable, supporting circular economy initiatives.

-

Low Waste Production: Extrusion generates 30% less scrap vs. CNC machining.

-

Certifications: CE Mark, ISO 14001, and DNV GL marine approval.

9. FAQs

Q: Can this heatsink operate in sub-zero temperatures?

A: Yes! Tested at -50°C with no loss of structural integrity or thermal performance.

Q: Is it compatible with high-voltage systems?

A: Absolutely. The anodized coating provides dielectric isolation up to 3kV.

Q: How to clean the heatsink in dusty environments?

A: Use dry compressed air (<0.3MPa). Avoid abrasive cleaners.